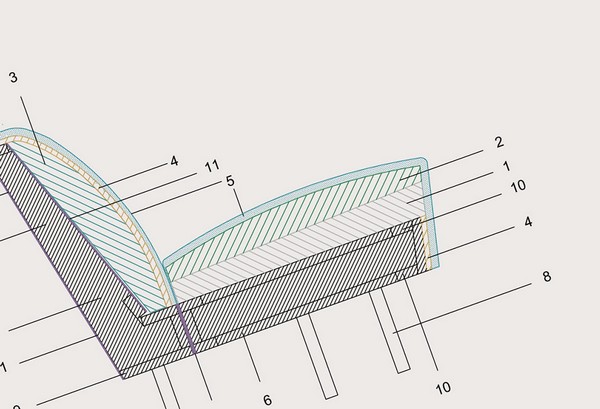

R&D

ATL Group develops in-house all the components

of the sofa, availing of a technical department

consisting of 22 technicians who follow the

product from design to prototype’s realization.

In a dedicated area of 1100 square meters,

besides the development department, main

production departments have been reproduced

on a small scale, from carpentry to foam cutting

dept, velvet cutting, fabrics cutting, sewing and

upholstery departments.

The Technical Department reaches in this way

such well-timed intervention and realization, that

allows to modify and evaluate in a short time

solutions and ideas during the development of the

models throughout designer visits.